Tutorial for Creating a Parabolic Dome Awning

Stephen M. Hollister,

Copyright 2002

This is a step-by-step tutorial to show you how to make a parabolic

dome-shaped awning using Pilot3D. The overall process is

·

Create a center axis line

·

Create the parabolic cross-section shape of the awning

·

Copy/Rotate the cross-section to create the 180 degree shape

·

Skin or fit surfaces to the rotated curves

·

Develop each piece to get the 2D pattern

Step 1 – After starting Pilot3D enlarge the “Front View” to use the whole

window area. You don’t have to do this, but I prefer working on one large

window at a time, rather than four small, separate windows.

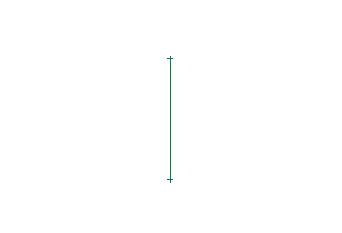

Step 2 – Create a centerline to use as the rotation axis for the awning.

Select the Curve-Add Polyline command. This command allows you to create a line

or polyline by picking the points with the left mouse button and terminating

the shape by picking the right button. In our case here, you want to enter

specific coordinate values for the center axis. This can be done by entering

the (x,y,z) values of the point instead of picking the left mouse button. So,

after selecting this command, type in “0,0,0” (without the quotes), followed by

the enter key. This will put the first point of the center axis at the origin.

Next, enter “0,0,3” to put the second point at 3 feet above the origin. Then

press the right mouse button to terminate the polyline input. You should see

what is shown below.

[Note: if you make any mistakes during this tutorial, you can always use

the Edit-Undo command (which is also the counter-clockwise arrow on the

toolbar).]

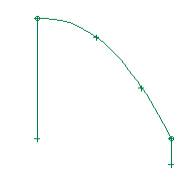

Step 3 – Create the parabolic cross-section shape of the awning. You

want to use the Curve-Add Curve command to add a curve, starting at the top of

the center axis. The Add Curve command works like the Add Polyline command in

that you enter curve points with the left mouse button and you terminate the

input using the right mouse button. However, for the first point, you want to

“snap” it to the top of the center axis polyline. This is done by positioning

the cursor near the top edit point of the axis line and pressing the ‘p’ key on

the keyboard (snap to a Point) rather than picking the left mouse

button. After you do this, you want to use the left mouse button to add a few

points to define a nice parabolic shape to the curve, as shown below. Don’t

worry about the straight, vertical piece at the bottom. You will add that in

the next step. Remember to use the right mouse button to terminate the

parabolic curve shape. Also, don’t worry about getting the exact shape that you

want right now. You can always go back and use the Edit-Move Point command to

change the shape of the curve after it has been created.

Step 4 – To add the short, straight vertical piece at the bottom, you

want to use the Curve-Add Polyline command. Remember to snap the first point of

the polyline to the bottom of the parabolic shape using the ‘p’ key on the

keyboard.

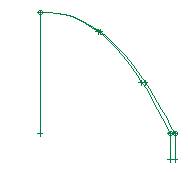

Step 5 – Use the Edit-Move Point command to change the shape of the

cross-section curves until you get the shape that you want – something like the

picture shown below. If you move and separate the common point between the

parabolic part and the vertical straight piece, you can use the Edit-Merge Pnt

To Pnt command to make sure that the two pieces remained attached.

[Note: Pilot3D has a whole set of fine-tune shaping and smoothing

commands for curves and surfaces, but they will not be discussed in this

tutorial.]

Step 6 – Now that the center axis line and the parabolic cross-section

shapes have been created, it’s time to make copies of the cross-section curve

and rotate them about the center axis. To make the job easier, you need to

first tell the program what you want to use for the central rotation axis. This

is done with the Modify-Rotate Entity/Group-Pick Rotate Axis 2 command. This

command lets you pick two points to specify a rotation axis. After selecting this command, use the ‘p’

key to snap or pick the bottom point of the center axis polyline. Then use the

‘p’ key again to snap or pick the top point of the center axis. You will

immediately see a dialog box like the one below that shows you the two points

that you picked for the center axis – (0,0,0) and (0,0,3), which are the two

coordinate values you originally used to create the center polyline. You should

also go to the “Rotation Angle” field and enter 15 for the rotation angle,

since we will be creating awning surface panels that cover 15 degrees of the

180 degree half-circle shape of the awning.

Once you have entered the 15 degree rotation angle, pick the OK button.

Note that nothing happens yet, since this just sets up the default

rotation axis.

Step 7 – Select the Modify-Rotate Entity/Group-Copy Rotate by Axis

+Angle command and then pick the parabolic curve. You will see the same dialog

box as shown above (already filled in), so just pick the OK button. This

command will create a copy of the first parabolic curve and rotate it by 15

degrees around the center rotation axis. Since the bottom vertical piece is a

separate entity, you need to pick that one separately to create a rotated copy.

[Note: Pilot3D uses something

called a default command technique. This means that when you select a command

to use (the Copy Rotate command in this case), you don’t have to re-select it

to use it again. This command will stay current until you select another

command. The current command is shown in a box in the lower right status line

of the main program window.]

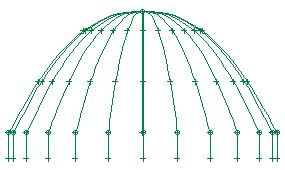

This means that you can keep using the Copy Rotate command for each

curve, one right after another. After using the Copy Rotate command for each

part of the cross-section curve, you should see something like what is shown

below.

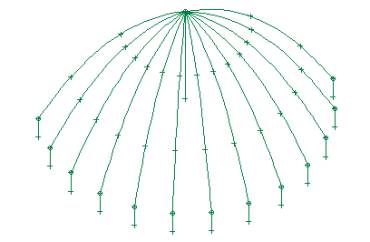

Step 8 – Since the default rotation angle is 15 degrees, you need to

keep using the Copy Rotate command on each of the new curves that are

created (not the original cross-section curves). Keep using the Copy Rotate

command until you have added 12 new parabolic curve shapes and 12 new vertical

pieces, as shown below.

Step 9 – To verify the shape, you can select the “3D” command on the

toolbar as, shown below. Then you can use the rotate commands (the ‘Z’ buttons

with the clockwise and counter-clockwise arrows) to better view the shape that

you have created. The “UP” and “DN” (down) buttons allow you to tilt the shape

up or down while you rotate it back and forth.

![]()

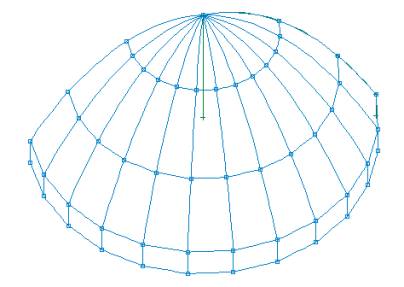

After rotating and tilting the shape, you should see something like what

is shown below. This shows the 3D

wireframe shape of the awning, which is ready for skinning with surfaces.

Remember, our first goal is to define all of the seam or structure lines with

curves, which we have just done.

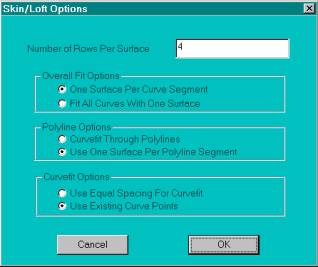

Step 10 – To fit the area between each set of two consecutive curves

with a surface, we need to use the Create 3D-Skin/Loft command. After selecting this command, you need to

pick (left mouse button) each curve (in sequence order) to tell the program

which curves to skin or fit with a surface. In our case here, we will be

skinning or fitting a surface between each consecutive set of cross-section

curves. In other words, we want to fit surfaces to each of the 12 separate

sections of the awning. As you pick

each curve, you need to pick the curves near the same ends. This tells the

program how to connect the two curves with the surface. [Remember that what is

obvious to a human is not so obvious to a computer program!] Once you have

picked two consecutive curves, pick the right mouse button to show the

dialog box below. For the parabolic curve part, you want to make sure that the

“Use Existing Curve Points” option is picked. This is not required, but it

makes a better fit for this example.

Next, pick the OK button to create the surface.

[Note: This is a powerful command that allows you to fit many curves

with multiple surfaces at the same time. However, we will not take the time

here to go into the details.]

Step 11 – Keep using the Skin/Loft command to create the rest of the

surfaces (12 parabolic pieces and 12 rectangular pieces). Remember that you do

not have to keep selecting the Skin/Loft command, since the program made it the

current/default command as shown in the lower right box on the screen. You just

keep picking the two consecutive curves and then picking the right mouse button

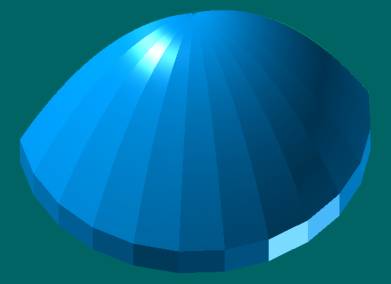

to bring up the dialog box. Once done,

you should see something like what is shown below in the3D view. The curves

have been replaced by the surfaces. [The curves are still there, but they are

turned off.]

Below is the same view in the View-Render View option.

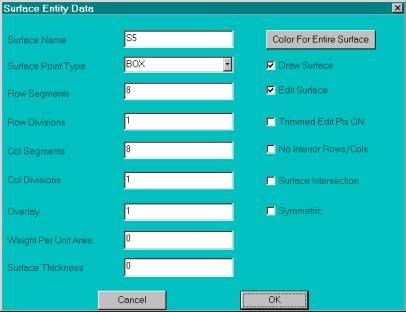

If you want to change the default colors of a surface, use the right

mouse button and click on the surface (somewhere other than along a common edge

between two surfaces). This will display the attribute/option box for the

surface, as shown below. Notice that one of the options is a color choice

option that you can use to set the color of the surface.

Below is what the awning looks like when every other surface has been

changed to orange.

Step 12 – Now you can unwrap or layout any surface that you want using

the Develop-Develop Plate option. After selecting this option and picking a

surface, you should see the dialog box shown below. It contains many options,

but for now, you can accept the default options and just pick the OK button.

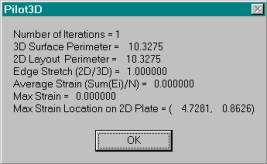

After the calculations are done, you will see a dialog box like the one

shown below. Pilot3D uses a finite

element analysis technique to flatten out the 3D shape into its 2D pattern. In

this case, the shapes are simple with no complex curvatures and no strains in

the material.

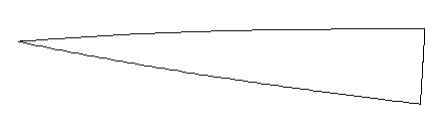

After you pick the OK button, you should see the following pattern for

one of the parabolic surface sections.

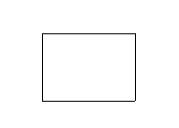

This is the 2D pattern for the rectangular section.

Of course, we didn’t need to model the entire 180 degree awning shape if

all we wanted were the two patterns above, since all of the patterns are the

same. However, the complete model is

nice for viewing and marketing purposes.

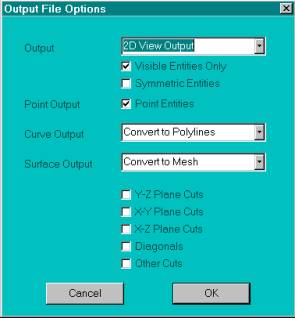

Step 13 – To get the full-size plotted patterns, just use the print

command. [You may need to go to the Options-Mod/Doc Definition dialog box to

set the values to a user-selected scale factor and set the scale to 1 foot

equals 1 foot.] To send the patterns to

a CNC machine compatible format, you need to display the pattern on the screen

and then select the File-Data File Output-DXF Output command. The following

dialog box will appear. The only value that you have to change is the Output

field from 3D output to 2D View Output. Then pick the OK button.

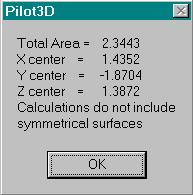

Step 14 – If you want to calculate the amount of material you need,

select the Calc-Surface/Group Area-3D Area command. When you pick a surface,

the 3D area and center will be calculated and displayed as shown below. To get

the total area of the awning, you will have to multiply the sum of the areas of

the two-surface section by 12.

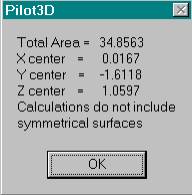

You can also get the total area by first using the Edit-Group

Entities-All Surfaces command first. Then, when you use the Area 3D command and

pick any surface, the command will be applied to the whole set of surfaces and

the results will be displayed as shown below. [Most commands work for one

entity if the picked entity is not part of the current group. However, if the

picked entity is part of the current group, many commands apply to the entire

group of entities.]

That’s it! This process is not completely automatic, but with a little

bit of practice you will be making 2D patterns for some complicated, creative

shapes.